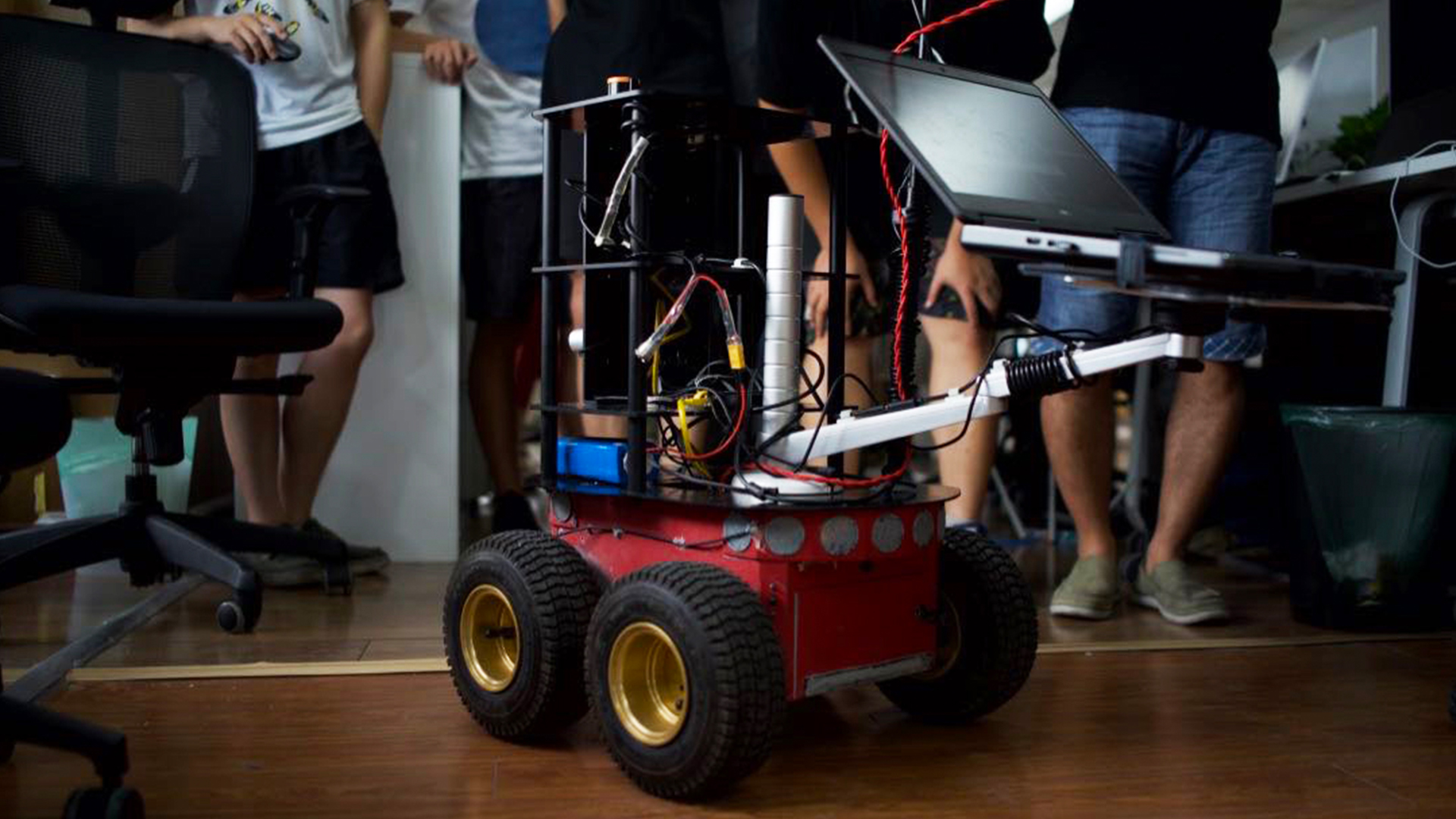

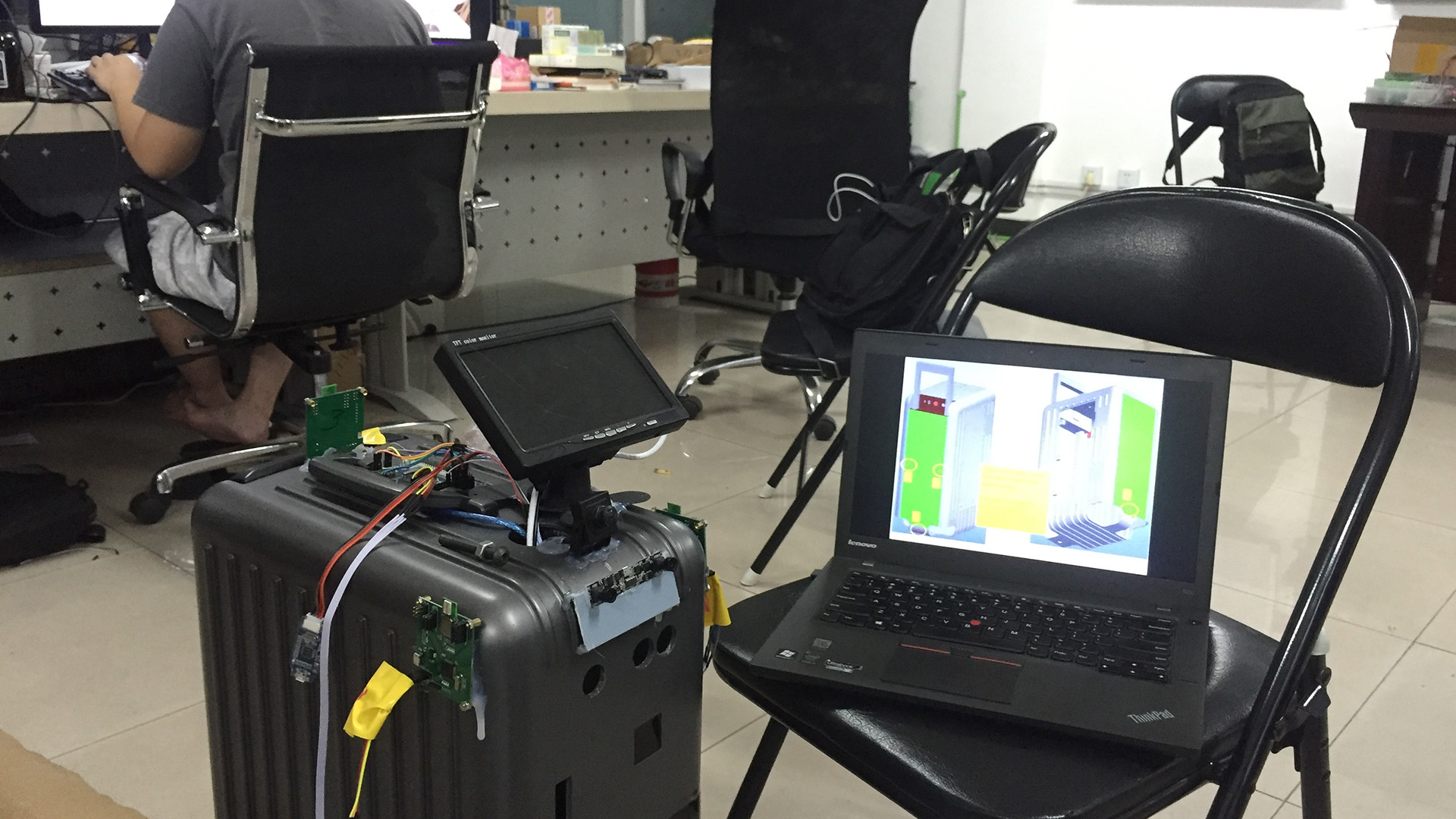

When the ForwardX founding team first approached us with their idea, we were initially skeptical but excited by the challenge. This uncharted territory presented an opportunity to validate the commercial relevance of personal robotics while building our expertise in computer vision and robotics design.

With no existing reference products to learn from, the journey to create a robotic suitcase was one of discovery. We had to ask ourselves: which camera, motor, battery, or PCU would be required to power a suitcase? And what about practical considerations, such as whether the case could pass through check-in scanners? The list of questions and challenges was endless.

When the ForwardX founding team first approached us with their idea, we were initially skeptical but excited by the challenge. This uncharted territory presented an opportunity to validate the commercial relevance of personal robotics while building our expertise in computer vision and robotics design.

With no existing reference products to learn from, the journey to create a robotic suitcase was one of discovery. We had to ask ourselves: which camera, motor, battery, or PCU would be required to power a suitcase? And what about practical considerations, such as whether the case could pass through check-in scanners? The list of questions and challenges was endless.