Commercialising a new form of transportation is complex, and the real test begins when you start to move into the production phase of the project.

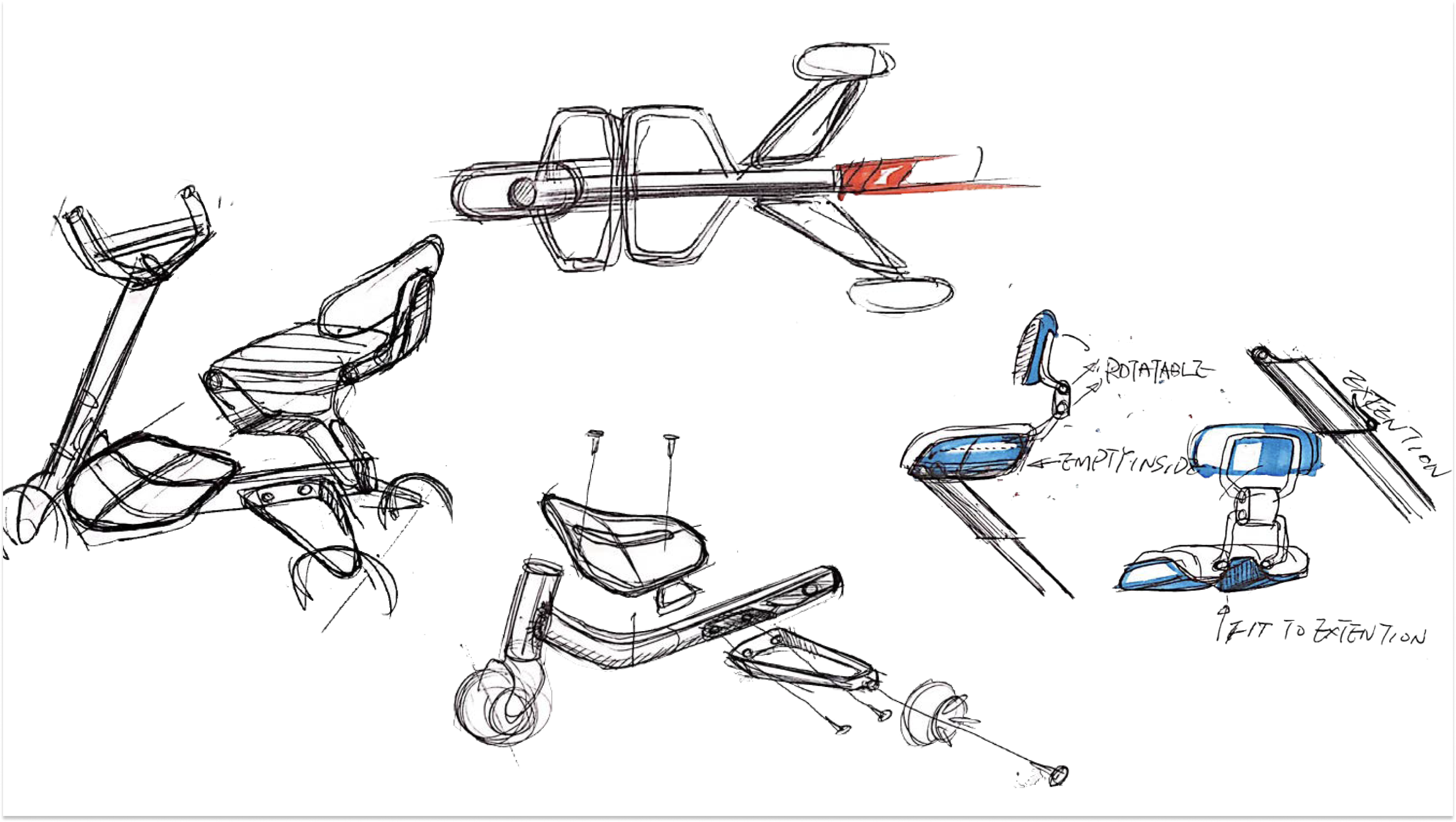

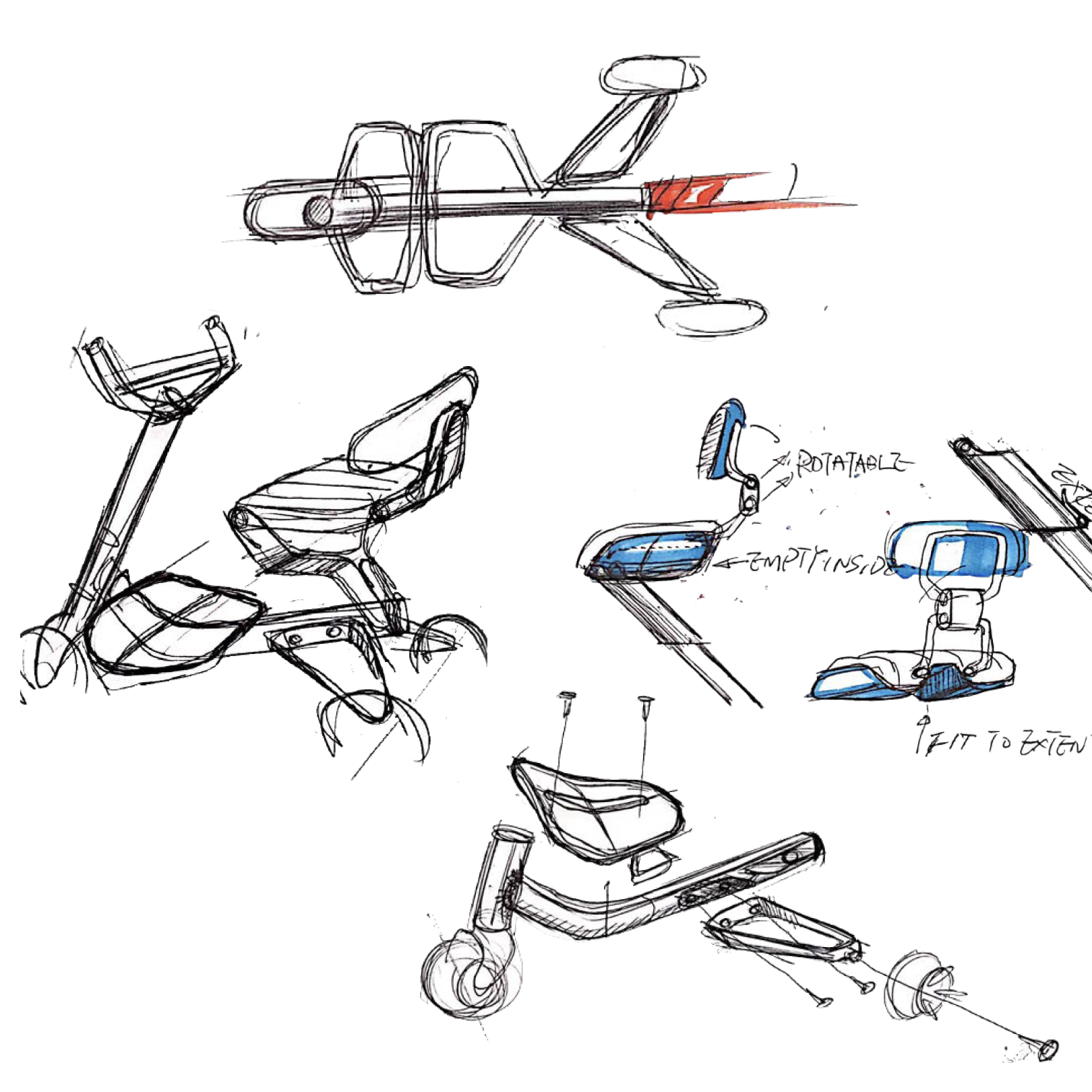

The need to build a team of trusted partners was evident, and this process began as soon as we had the first concept drawings. The best place to create this type of product is China, and with our local engineering & design teams on the ground, we were halfway there.

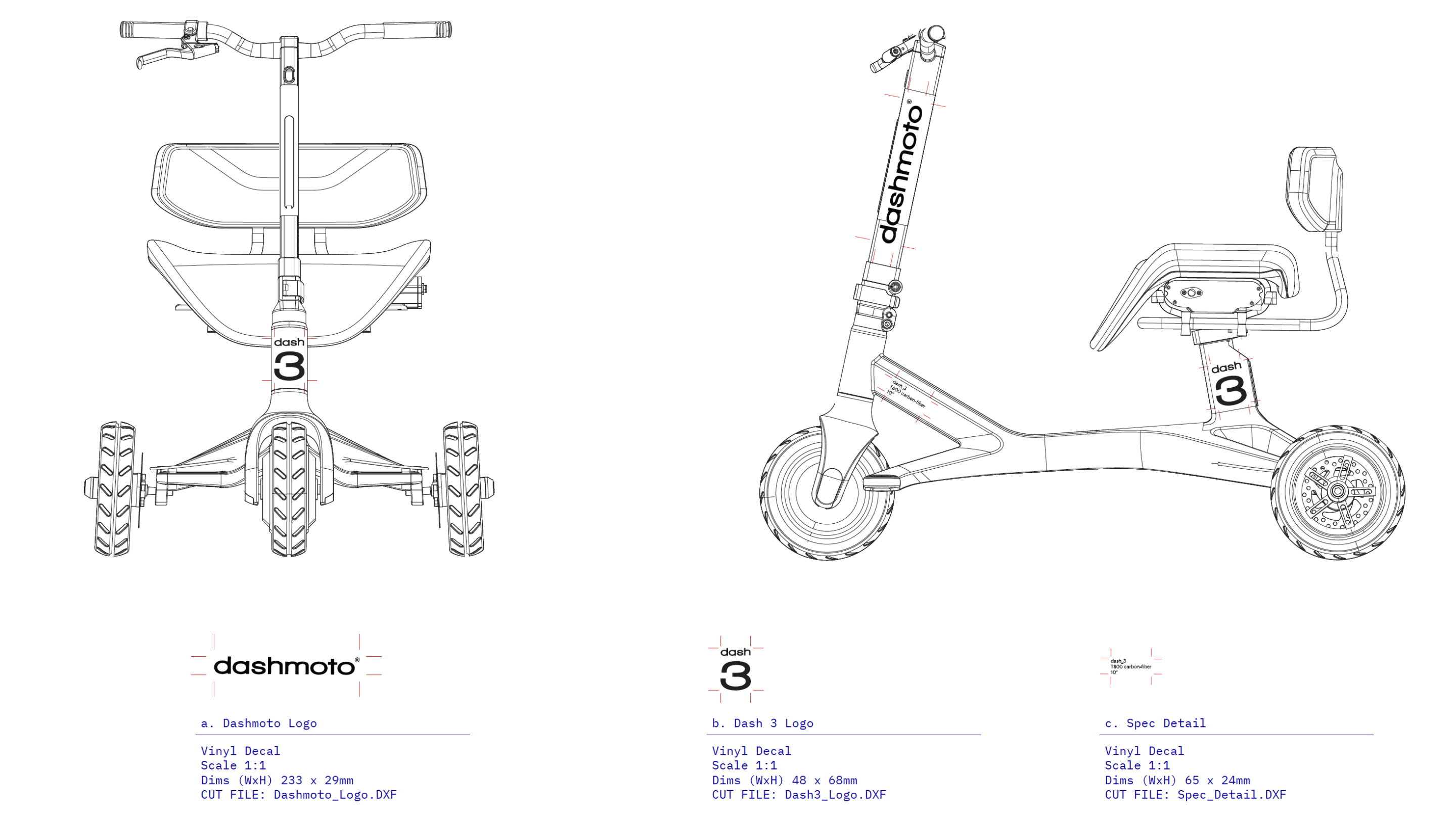

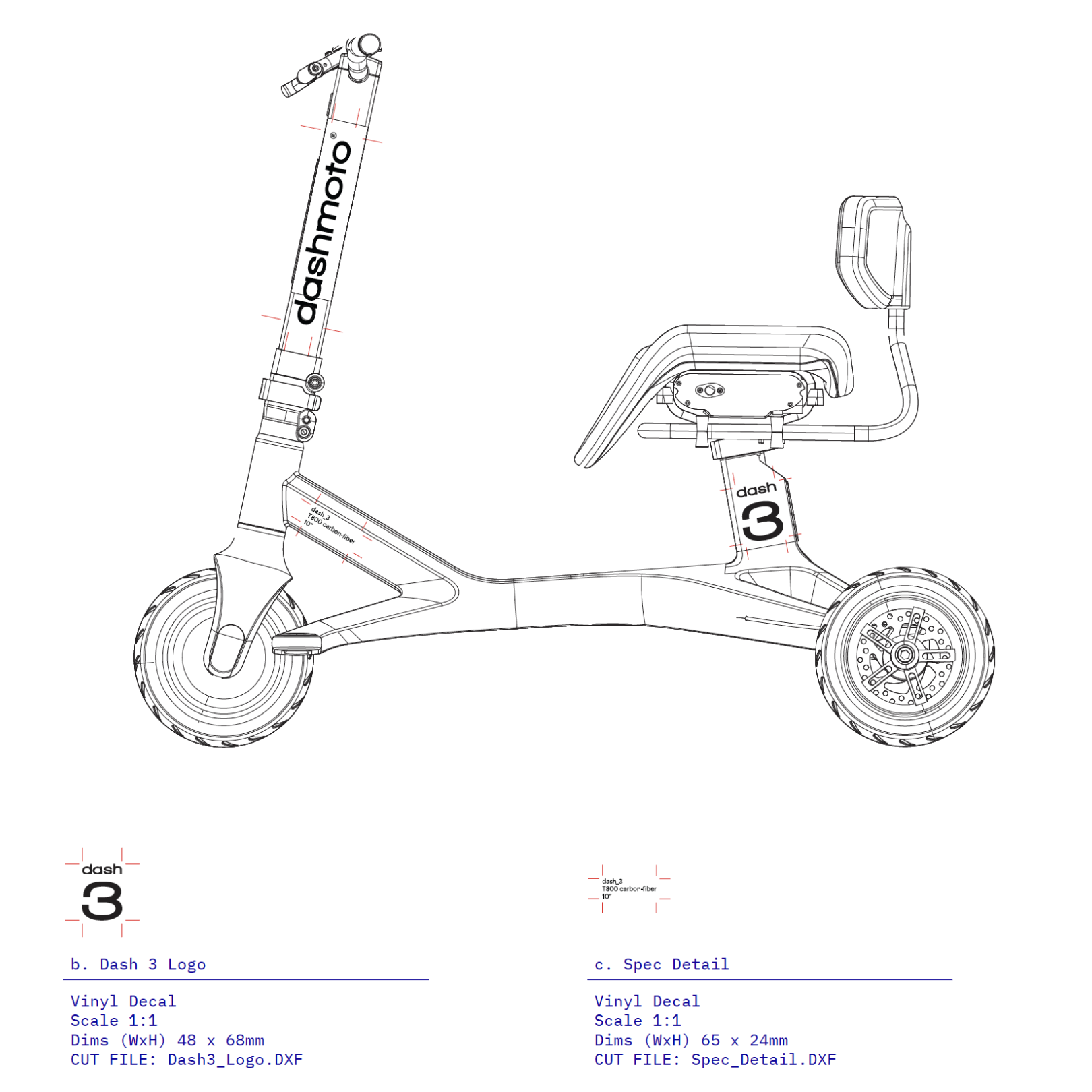

The co-creation process with your production partner will make or break a product. A good factory will help you fix problems and optimise the design, with their team acting as core members in your business, de-risking and developing a commercialisation model to ensure that long-term partnership.

Commercialising a new form of transportation is complex, and the real test begins when you start to move into the production phase of the project.

The need to build a team of trusted partners was evident, and this process began as soon as we had the first concept drawings. The best place to create this type of product is China, and with our local engineering & design teams on the ground, we were halfway there.

The co-creation process with your production partner will make or break a product. A good factory will help you fix problems and optimise the design, with their team acting as core members in your business, de-risking and developing a commercialisation model to ensure that long-term partnership.